Manufacturing Capabilities

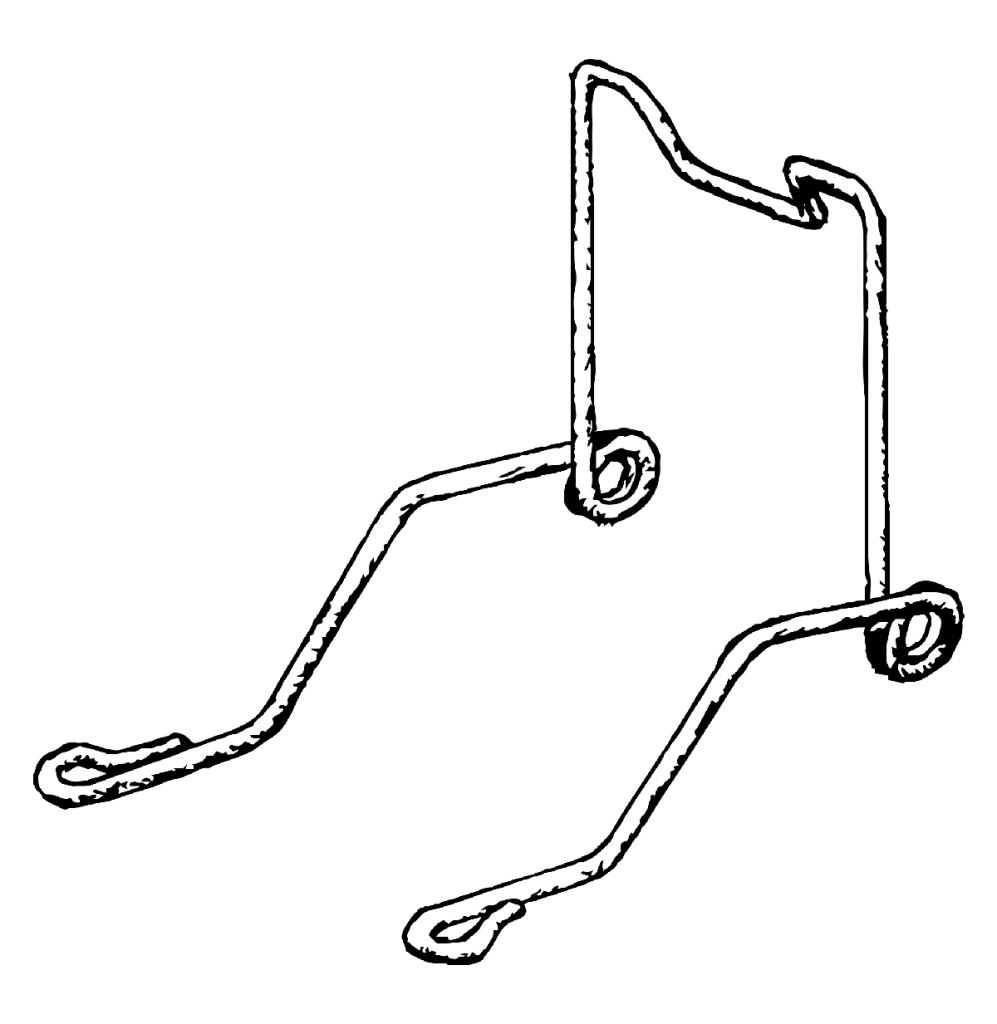

Wire Forms

Wire Forms range from simple handle constructions to complex parts with multiple bends. Gifford Spring specializes in both. We manufacture complex wire forms, levers, clips, and almost any other shape or bend to suit the customer’s application.

We utilize the latest available technology, including CNC and custom-built tabletop benders. Our precision bending equipment guarantees repeatability and maintains the closest possible angle tolerances. Unique in our industry, we incorporate both basic and spring-tempered wire in manufacturing the custom wire forms we produce.

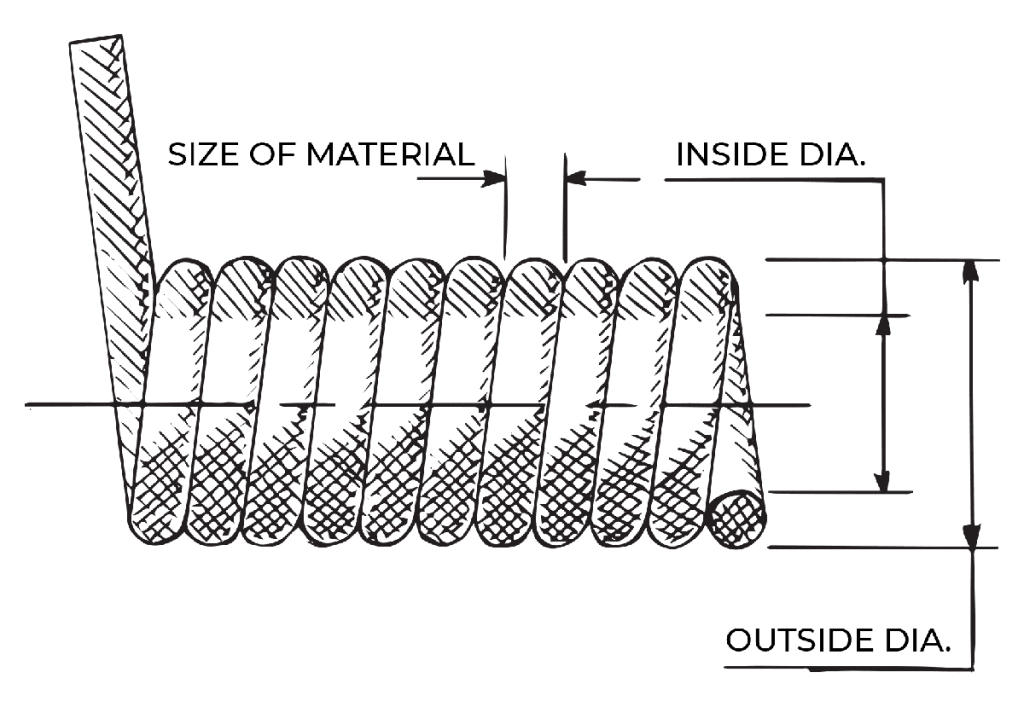

Compression Springs

Compression Springs are open-coiled helical springs that resist compressive force.

These springs are manufactured in cylindrical, conical, concave (hourglass), convex (barrel) or any shape to suit the application and are typically made with round wire.

Closed ends are preferred because they allow a greater degree of squareness and prevent tangling. Grinding the ends permits even more squareness control and inhibits buckling.

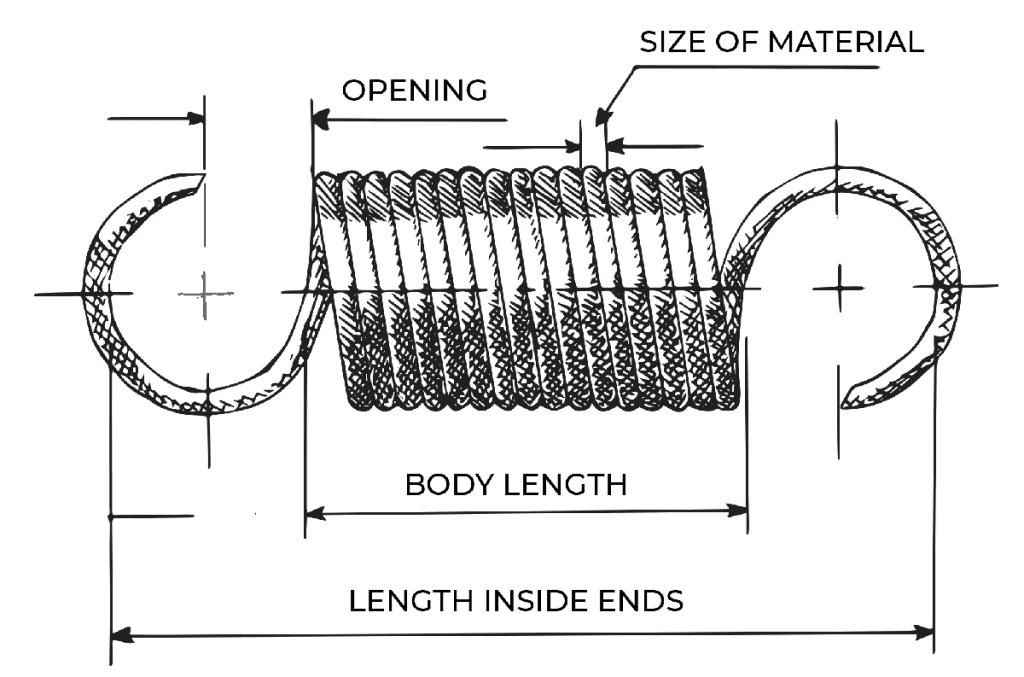

Extension Springs

Extension Springs work by their initial tension resisting the pulling force to which their ends are attached. Extension springs use various types of ends including machine hooks, crossover loops, side loops, and others.

The path of wire from the body of the spring to its ends should be as smooth, gradual and seamless as possible to maximize the life of the spring. The most common extension spring material is round wire.

Torsion Springs

Torsion Springs work by resisting externally applied torque. Friction and arm deflection affect torque. Torsion springs are most effective when supported over a rod or tube.

Double torsion springs consist of one right-hand and one left-hand coil section connected to each other and working in parallel.

We frequently manufacture both plain-end custom torsion springs and those with multiple complex bends. Torsion springs are commonly manufactured from round wire.

Prototyping

At Gifford Spring Company, we recognize the need to stay ahead of innovations in technology, manufacturing processes and business practices. As industries such as aerospace, medical, and electronics revolutionize their own capabilities, their needs for custom wire solutions grow more sophisticated and complex. We at Gifford Spring push the limits of springmaking manufacturing to meet these demands.

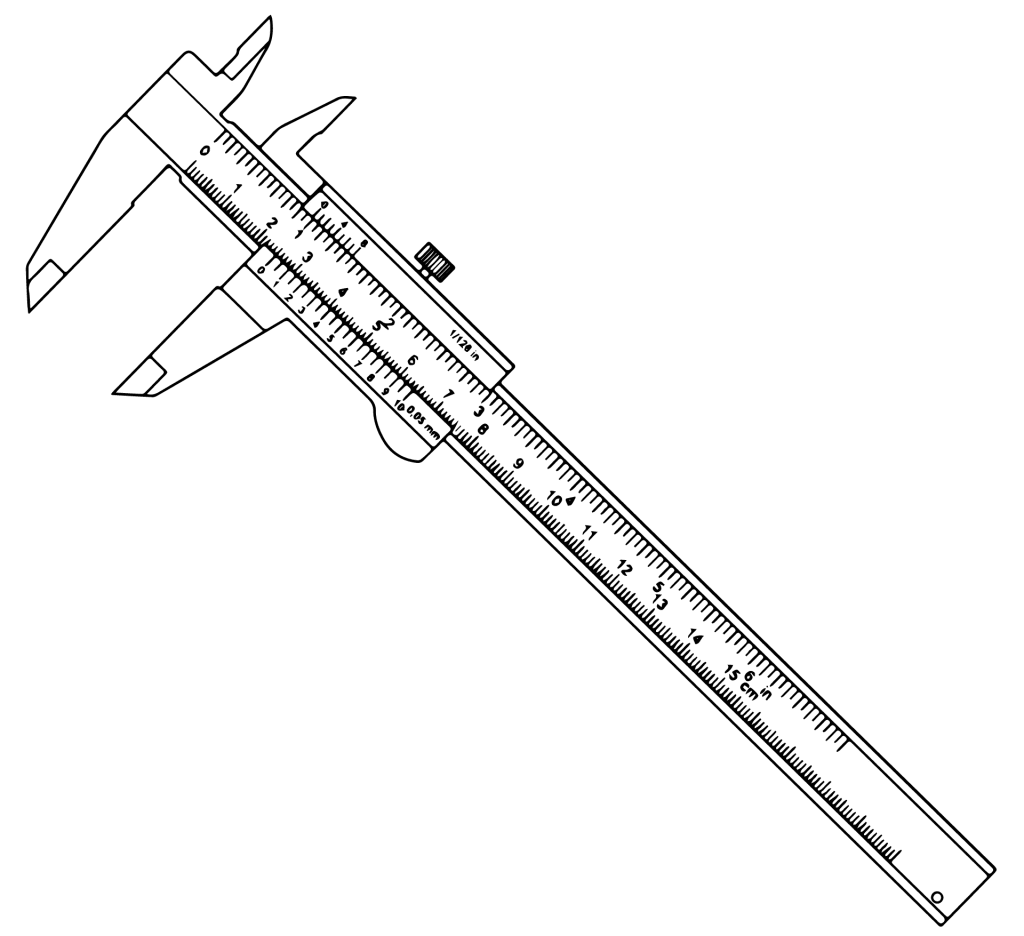

Our CNC and full 3D forming equipment are the most sophisticated available in our industry and maintain highly precise tolerances. Our certified calibration equipment used by carefully trained inspectors verifies that quality is preserved regardless of quantity produced.

The Gifford Spring Quality Control Department functions as an essential part of every step of the production process. Quality control is integrated throughout the manufacturing stream from the purchasing of raw materials to properly labelling the shipment box and every step in between, insuring the Gifford Spring standard of excellence is maintained.