Parts shipped in 2-4 weeks standard

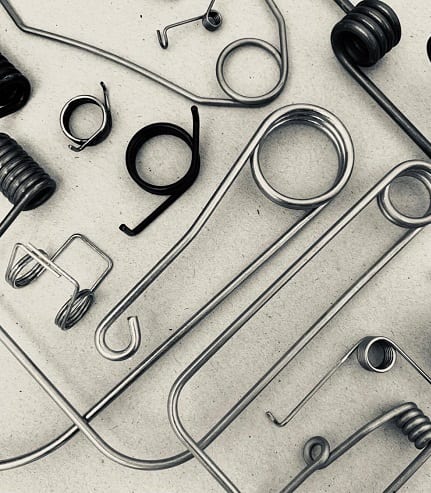

Custom Spring Manufacturing Services

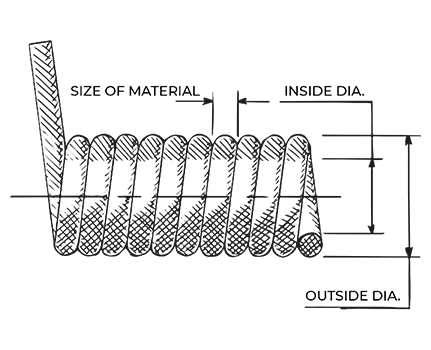

Compression Springs

Types of custom precision compression springs we manufacture include conical, hourglass, barrel, constant pitch, variable pitch, and more. Gifford manufactures both prototype and large-volume production runs of custom compression springs.

Extension Springs

Types of custom precision extension springs we manufacture include D-rings, S-hooks, and other customized shapes. Gifford manufactures both prototype and large-volume production runs of custom wire forms.

Wire Forms

Wire Forms range from simple handle constructions to complex parts with multiple bends. Gifford Spring specializes in both. We manufacture complex wire forms, hooks, rings, frames, and clips. Wire forms typically contain a combination of bends to suit the customer’s application.

Prototype Springs

We love quantity 1 and we are experts in manufacturing prototype springs. Types of custom precision springs we manufacture include compression springs, extension springs, torsion springs, and more.