Do you have an existing compression spring that you either need to replicate or modify? If you do, the first thing we will need are your manufacturing requirements. These will include material, finish, physical dimensions, and load requirements. In this blog, we will cover how to measure your compression spring so that you can provide accurate manufacturing specifications.

Measuring Compression Spring Physical Dimensions

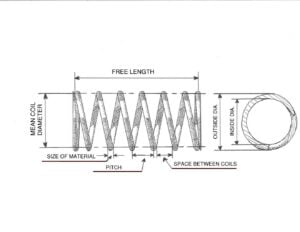

The most straightforward method to measure a compression spring is by examining its physical dimensions. Here are the key measurements you need to consider:

- Wire diameter: Measure the wire’s diameter using calipers to 3 decimal places.

- Free Length: measure the length of the spring right as your calipers make contact with the spring. Be careful to not compress the spring when measuring.

- Outside and Inside Diameters: Typically, the more critical of these two dimensions will be specified. If your spring fits inside of a shaft, the Outside Diameter would be specified. If your spring fits over a rod or pin, the inside diameter would be specified.

- To measure outside diameter, measure the end coils of the spring. These tend to be larger than the rest of the spring body.

- To measure inside diameter, measure the smallest inner diameter of the spring coils.

- Total Coils: To measure total coils, start with one end of the spring. Follow along the spring in the same spot, counting each time a full revolution is made. If there is a partial coil once you reach the end, you can estimate that fractional coil.

- Ends: Take note of the ends of your spring. Are they closed, do they have a grind?

Specifying Load Requirements or Spring Rate

If you know your load requirement or spring rate, you can further refine your spring specifications. This will ensure that your spring performs exactly as needed. If you don’t know your spring rate, Gifford Spring can determine it from a sample using our load testing machines.

Load Requirement: This is the force or weight your spring needs to support when compressed a specific distance, or to a specific length.

Spring Rate: The spring rate, often referred to as stiffness, indicates how much force is needed to compress the spring by a specific distance. It’s measured in force per unit of length (pounds per inch or newtons per millimeter).

The best way to specify your compression spring is by providing only your most critical dimensions. This approach ensures that your spring manufacturer can create a spring that precisely matches your needs. Providing too many dimensional requirements can over constrain the design and may impact manufacturing costs.

Measuring your compression spring correctly is vital for ensuring that it performs as intended within your application. By understanding the physical dimensions, load requirements, spring rate, material type, and finish options, you can work with a spring manufacturer to create the perfect spring for your needs.

At Gifford Spring Company, we specialize in manufacturing high-quality compression springs to meet a wide range of industrial and engineering needs. Contact us today to discuss your compression spring requirements, and we’ll work with you to deliver the precise solution you need.