So you designed a part that needs a spring. Now all you have to do is figure out how to source it. Simple, right?

Well, not exactly. If you don’t work with springs all the time, how do you know whether to stop by your local hardware store, order from a stock spring catalog, or visit a custom spring manufacturer?

Let’s break down the options.

Benefits and Drawbacks of Using Stock Springs

If you’re in the early stages of prototyping or working on a part that was designed to accommodate standard spring specifications, you may want to consider using stock springs.

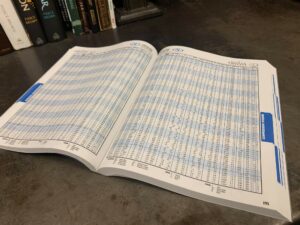

In most cases, your local hardware store won’t have the kind of spring you need. We recommend ordering from an online stock spring catalogue instead.

Stock spring catalogues offer a wide variety of standard springs to choose from—but you should know the benefits and drawbacks of this solution before moving forward.

Benefits of using stock springs:

- Low cost. It’s possible to order 1, 5, or even 10 springs online with a fairly minimal budget. Keeping costs low is ideal when you’re testing several springs to determine the approximate dimensions that work best for an application.

- Easy to source. If your design accommodates a standard spring or a MIL-SPEC compression spring for loads under 20 lbs., you’ll find exactly what you’re looking for in a stock catalogue. Stock springs are generally readily available.

- Fast turnaround. Because standard springs are held in inventory, ordering from a stock spring catalogue is quicker than having your spring custom made.

Drawbacks of using stock springs:

- Limited options. If you have non-standard measurements for dimensions such as spring length, outer diameter, or spring rate, you may not find the right solution in a spring catalogue. Remember, stock springs are made to standard specs—not yours! Likewise, if you’re looking for a custom material or finish, a stock spring may not be the right choice.

- Cost-prohibitive at volume. Stock springs are cost-effective when you only need small quantities—from one up to a few dozen. However, if you require a higher volume of parts, custom springs often end up being more cost-effective than stock options.

- Difficult to trace. If your project requires documentation with clear material traceability, you should know that this information may be difficult to acquire with a stock spring. Some documentation may be available online or from the manufacturer, but it’s not always easy to find.

When to Use Custom Springs Instead

If you’re unsure whether a stock spring will meet your needs, it’s probably time to call a custom precision spring manufacturer. If you’re still on the fence, here are a few questions that can help you determine if a custom spring is best for your design:

- Do I need to hold a specific dimension or spring rate? First, check online to see if there’s a stock option for your wire size, diameter, and length requirements. If you can’t find what you’re looking for, you’ll probably need a custom spring.

- Do I need more than 100 springs? Customers who need a higher volume of springs—again, “high volume” can be as little as a few dozen springs—typically benefit from placing an order with a custom spring shop instead of a stock manufacturer. So even if your spring is available in a stock size, you may still want to choose custom spring manufacturing for the cost benefits.

- Does my spring have tight tolerance requirements? Stock springs typically hold to standard commercial tolerance requirements as defined by the Spring Manufacturers Institute (SMI). But if you need tighter tolerances than that, a custom precision spring is the best way to guarantee them.

- Do I need a specific load height? Load height, a specific force required to achieve a specific compressed/extended length, may not be a critical requirement for your application. But if you do need a specific load height that is verified during production, it’s usually only achievable with a custom spring.

- Do I need an extension or torsion spring? Compression springs are generally easiest to source from stock. Extension and torsion springs, on the other hand, can be more difficult to find. Extension springs are often designed with unique spring hooks, and torsion springs may require specific angles between the legs, making these types of springs excellent candidates for customization.

When you need a custom spring, you can trust Gifford Spring to deliver. Request a quote today!