Uncategorized

Wire Form Finishes: Considering Aesthetics in Your Design

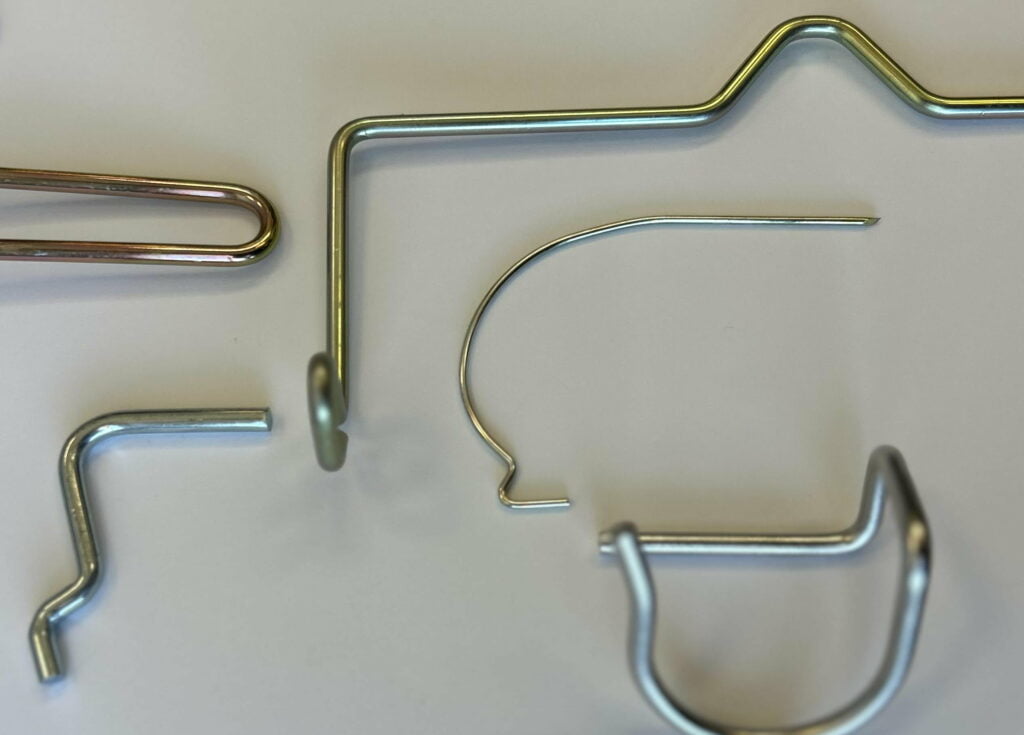

Wire forms like handles, display hooks, food-service equipment, and medical equipment require careful attention to both appearance and functionality. In this blog post, we will explore various wire form finishes and materials to consider when aesthetics plays a crucial role in your design. Most wire forms are not visible when assembled into a final product…

Read MoreHow to Measure your Compression Spring

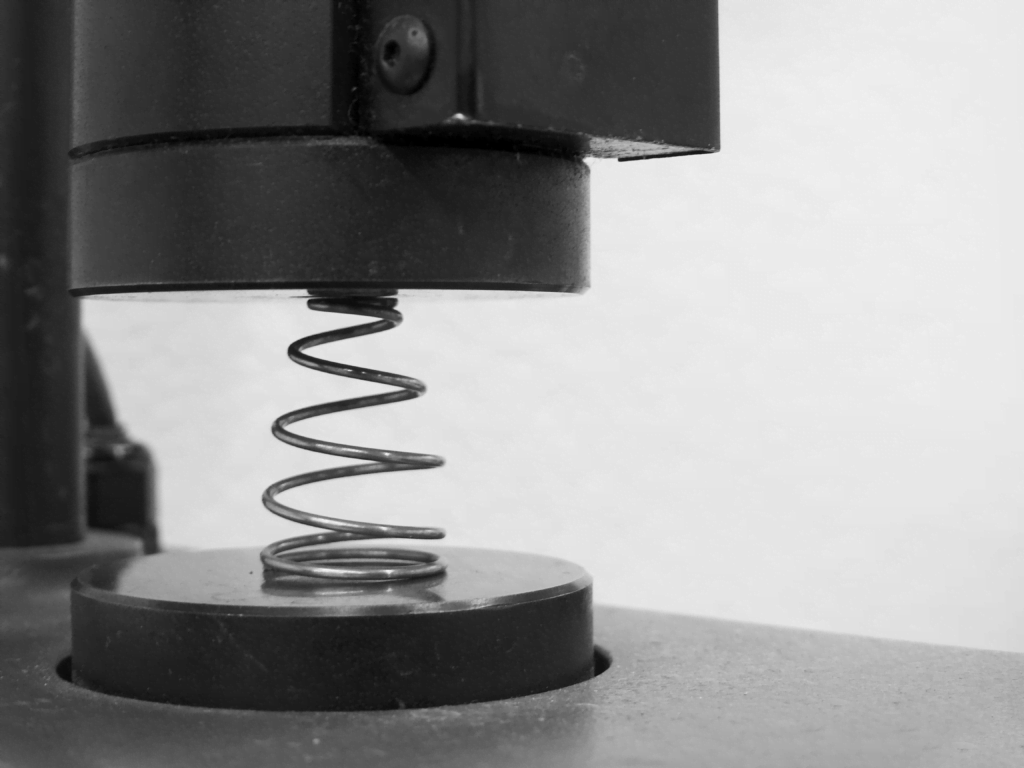

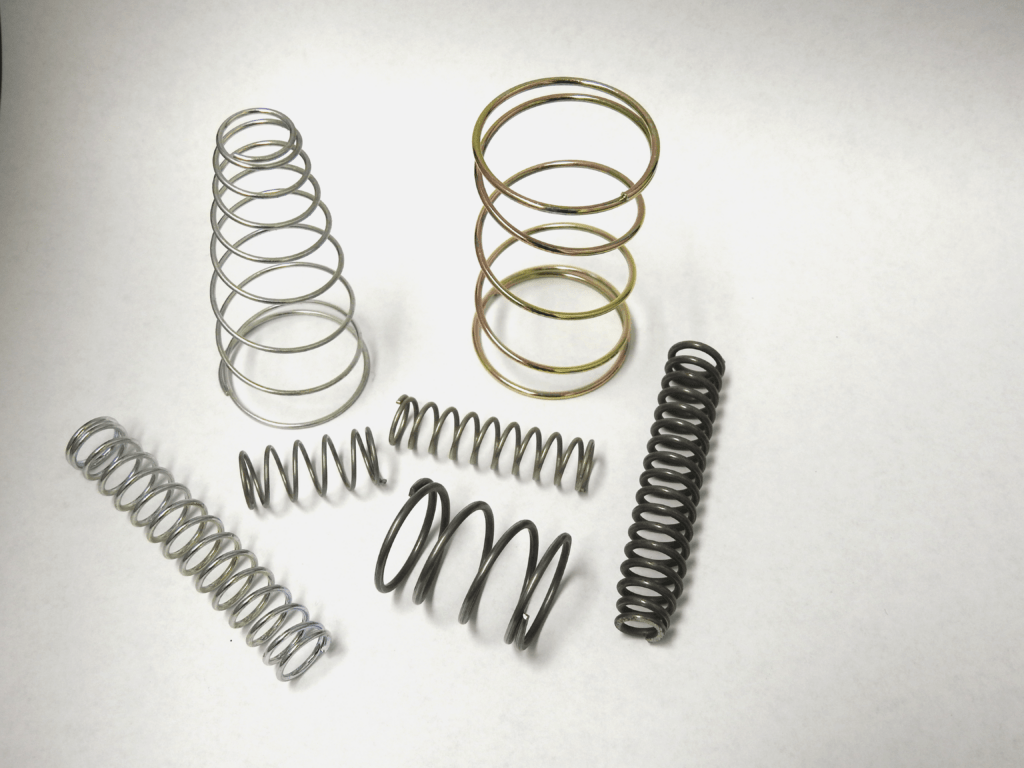

Do you have an existing compression spring that you either need to replicate or modify? If you do, the first thing we will need are your manufacturing requirements. These will include material, finish, physical dimensions, and load requirements. In this blog, we will cover how to measure your compression spring so that you can provide…

Read MoreDelivering Excellence: The Gifford Spring Advantage

Delivering Excellence: The Gifford Spring Advantage In critical industries like aerospace and manufacturing, the demand for precision in spring and wire form manufacturing is non-negotiable. At Gifford Spring Company, we understand the pivotal role these components play in high-stakes applications. We are committed to delivering only the highest quality products, ensuring they are manufactured as…

Read MoreHow do wire form prototypes work?

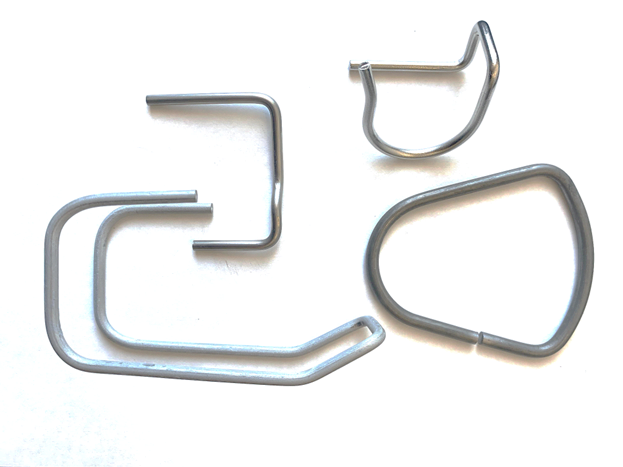

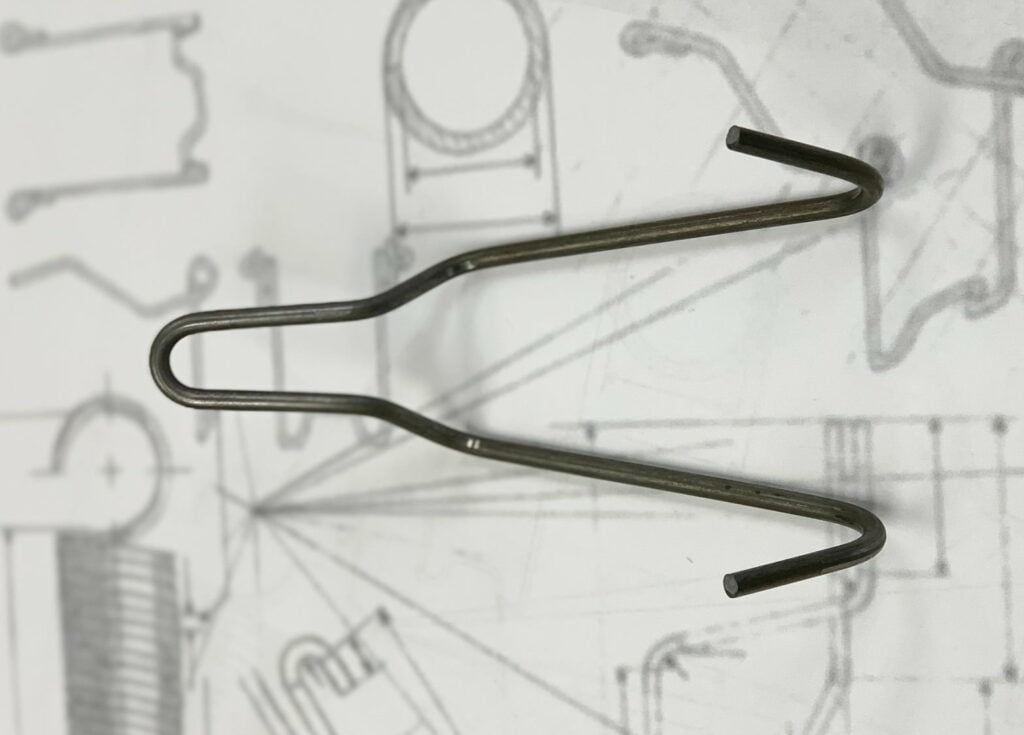

Thinking about getting a wire form prototype made before going into full production? If you need a proof of concept or anticipate design iterations, a prototype is the best place to start Whether you know exactly what type of wire form you need or have no idea where to begin, wire form prototyping provides a…

Read MoreHeat Treating Springs: Enhancing Spring Performance

To ensure optimal functionality and prolonged lifespans for springs, manufacturers rely on a crucial process called heat treating. In this blog post, we will delve into the fascinating world of spring heat treating, exploring its significance, methods, and benefits it brings to these essential mechanical components. The Role of Heat Treating Springs When manufacturers form…

Read MoreHow to Incorporate a Wire Form into Your Assembly

Do you need to incorporate a wire form into your assembly? At Gifford Spring, we actively engage in wire form design discussions with our customers, offering cost-effective solutions to enhance strength, functionality, and precision in assemblies. Wire forms can often serve as more affordable alternatives to metal castings and machining. In this article, we will…

Read MoreTaking Your Custom Springs from Prototype to Production

Want to transition your custom spring seamlessly from prototype to production? Your best bet is to work with a spring manufacturer with expertise in both manufacturing stages that can facilitate the progression from one stage to the next. Here are the top reasons Gifford Spring Company customers choose to work with our team for prototyping…

Read MoreThe Top 3 Reasons Springs Fail

In our almost 40 years of manufacturing high-quality custom springs at Gifford Spring Company, we have seen many factors that can lead to spring failure. Our experience has given us valuable insight into the key reasons your springs could fail as designed, and more importantly—how to prevent a spring from failing. Reason #1: Issues…

Read More6 Design Considerations for Custom Compression Springs

When you hear the word “spring,” it is likely that the image of a compression spring comes to mind. Compression springs are the most common of all spring types. As the name suggests, compression springs are designed to compress when force is applied. These springs deflect in a linear motion, resisting the applied force and…

Read More5 Design Considerations for Custom Extension Springs

With hooks on both ends, extension springs attach to two components in an application and resist tensile forces, elongating as those components pull away from one another. An extension spring stores energy as it elongates creating a pulling force between the components. Extension springs are used in many common and industrial applications, including: Farm equipment…

Read More