Uncategorized

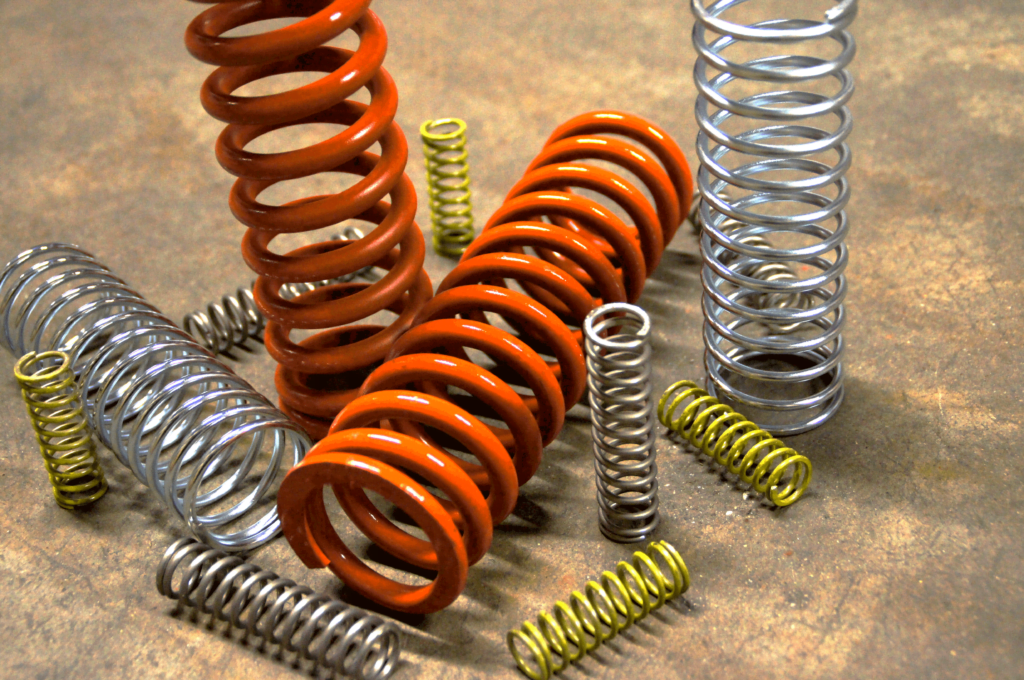

How Design Impacts Cost: Springs and Wire Forming

With the twin pressures of inflation and supply chain challenges continuing to impact manufacturers, keeping cost in mind for spring and wire forming services remains a high priority for our customers. At Gifford Spring Company, we are here to support you. — Here are a few factors that directly impact the cost of your parts.…

Read MorePlan Ahead to Mitigate Supply Chain Challenges

At Gifford Spring Company, meeting (and exceeding) our customers’ expectations is our top priority. That means making sure we can provide the parts you need today—as well as six months or a year from now. It is no secret that supply chain challenges have significantly impacted the manufacturing industry since 2020. While recent indicators show…

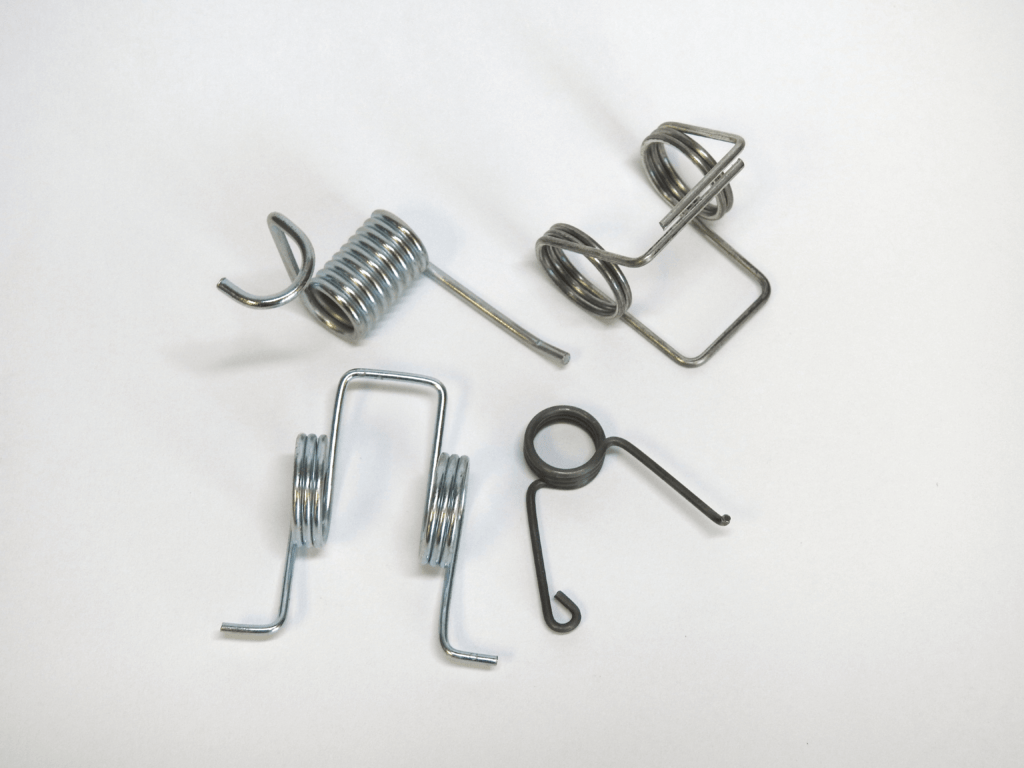

Read More5 Design Considerations for Torsion Springs

Do you need a custom torsion spring for your assembly? Torsion springs are an excellent choice for mechanisms that require rotational force or resistance (torque). With legs extending from both sides of the spring’s coils, the torque is transferred from the spring’s coils, through the legs, then to the component attached to the legs. Depending…

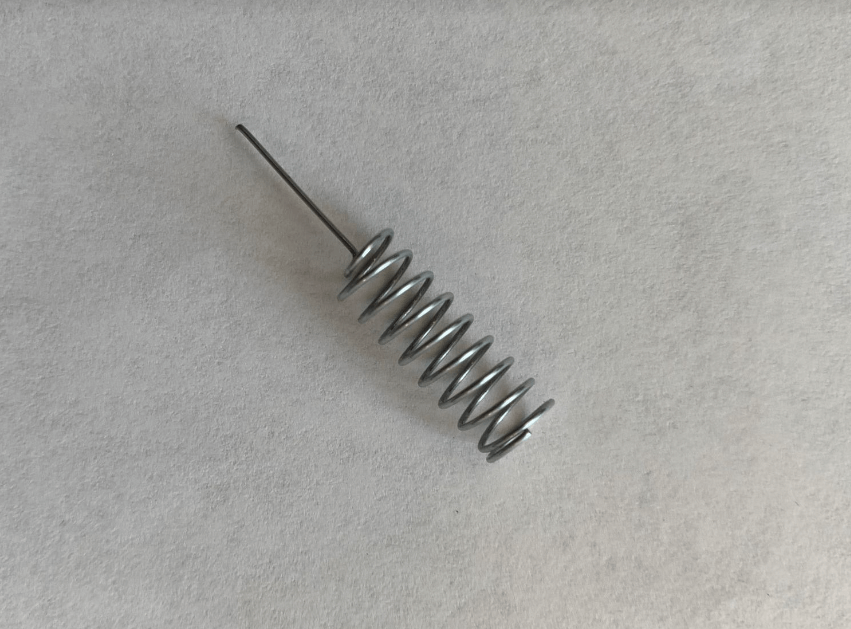

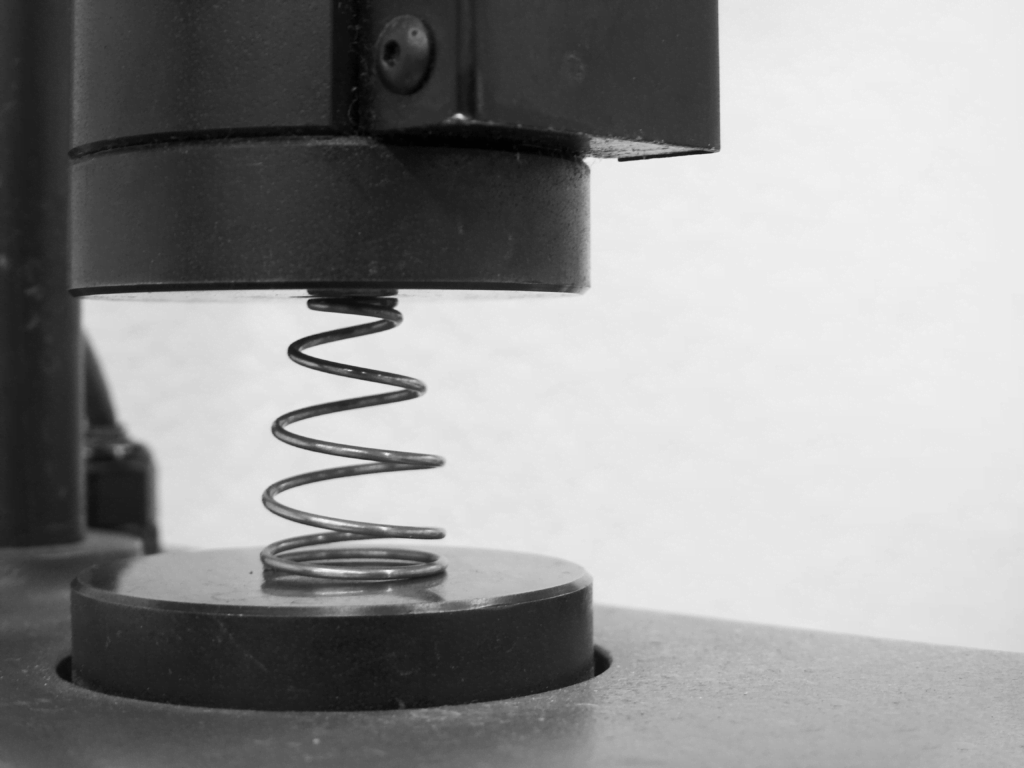

Read MoreThe Importance of Load Testing in Custom Spring Manufacturing

Customers often think the best way to ensure their custom spring functions as intended in an application is to carefully define the spring’s physical dimensions such as free length or number of coils. While that information is important, there is a tried and true way of simulating a spring’s function in its end-use environment: a…

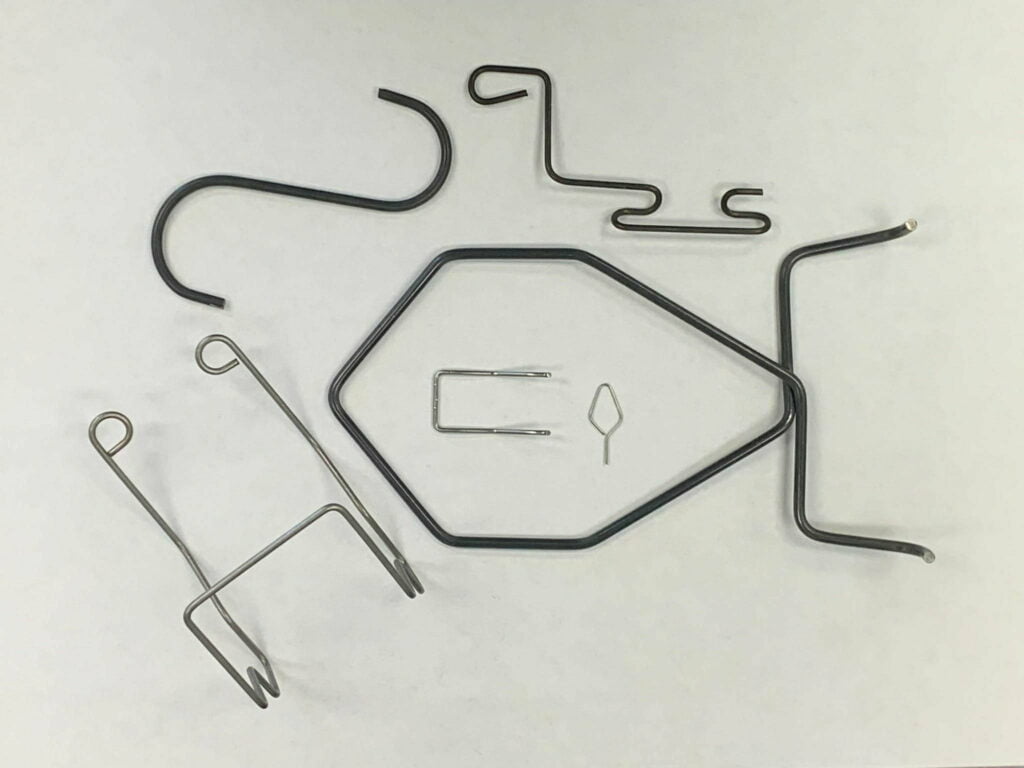

Read MoreMaterial Options for Custom Wire Forming Services

At Gifford Spring Company, we can form just about any round material into a custom wire form. But we like to dig deeper with our customers so that they feel confident they are using the best material possible for their specific applications. When selecting a material for your wire form, it is critical to look…

Read MoreCustom Spring Manufacturing for a Contract Welding Company in the Oil & Gas Industry

As a trusted custom spring manufacturer, we work with many customers whose specific needs cannot be met by the items in an online stock spring catalog. Often, customers are unsure if their vision can become a reality, but at Gifford Spring Company, we do everything possible to bring even the most complex ideas to life. …

Read More9 Questions Your Custom Spring Manufacturer Should Ask You

When preparing to produce a custom spring or wire form, a great custom spring manufacturer will initiate a conversation with you to gain a thorough understanding of the component’s end use. Even if you have provided comprehensive specs and part documentation in your quote request, this initial dialogue helps ensure that both parties—customer and manufacturer—are…

Read More6 Tolerance Guidelines for Wire Forming Services

Tolerancing standards for custom wire forming applications are different from those used for precision machined parts, as well as custom springs. Most methods of machining (such as turning, milling, and drilling) can hold exceptionally tight tolerances. Machining tolerances typically cannot be applied to springs. Instead, springs have well-defined tolerance criteria put forth by the Spring Manufacturers…

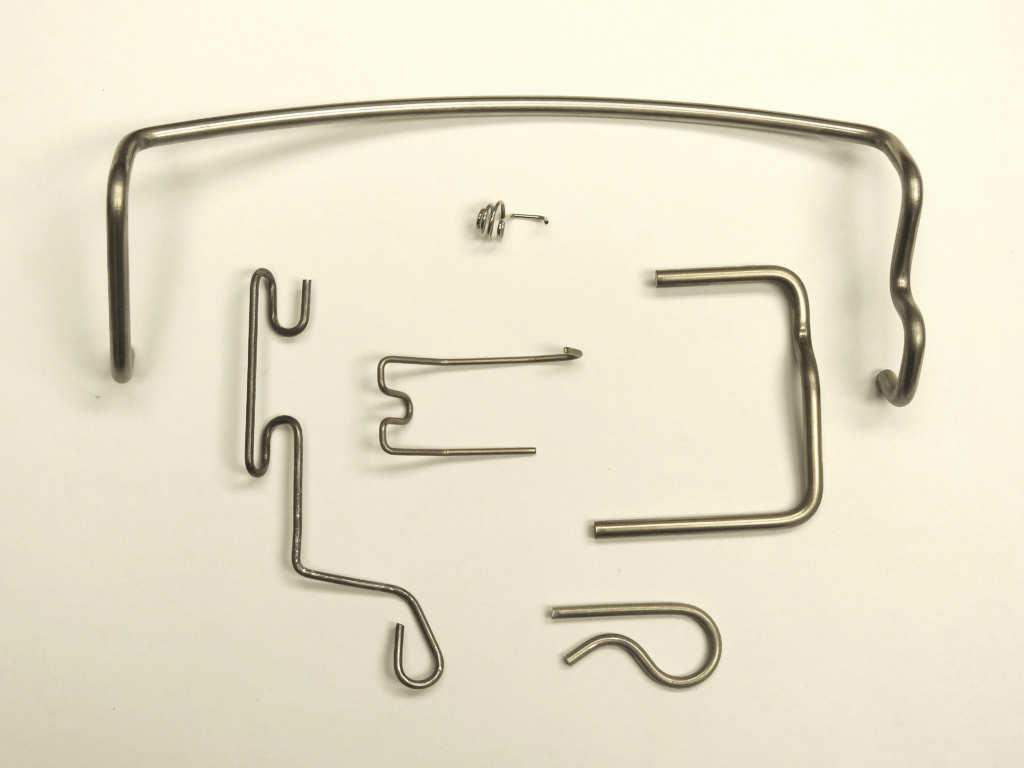

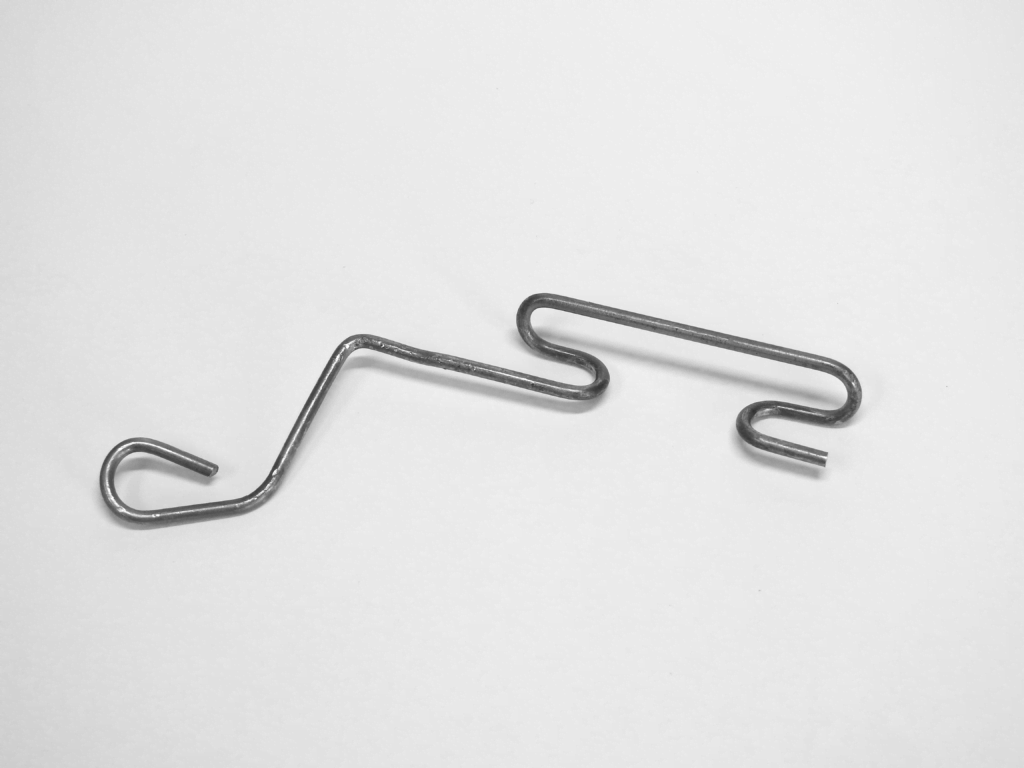

Read MoreDesign Tips for Wire Forming

Curious about how to optimize your wire form design? At Gifford Spring, we’re committed to helping our customers save time and money on custom springs and wire forms. Today, we’re sharing Design for Manufacturability (DFM) tips for wire forms so you can enjoy faster quotes, shorter lead times, and lower costs. We can summarize most…

Read MoreAre Surface Finishing Operations Necessary for Custom Springs and Wire Forms?

Curious if your custom springs or wire forms need surface finishing operations such as plating or electropolishing? More often than not, they don’t. When alternatives are available, we advise customers to forgo secondary operations when possible to avoid the inherent risks involved in finishing parts. Today, we’ll take a closer look at the benefits and…

Read More